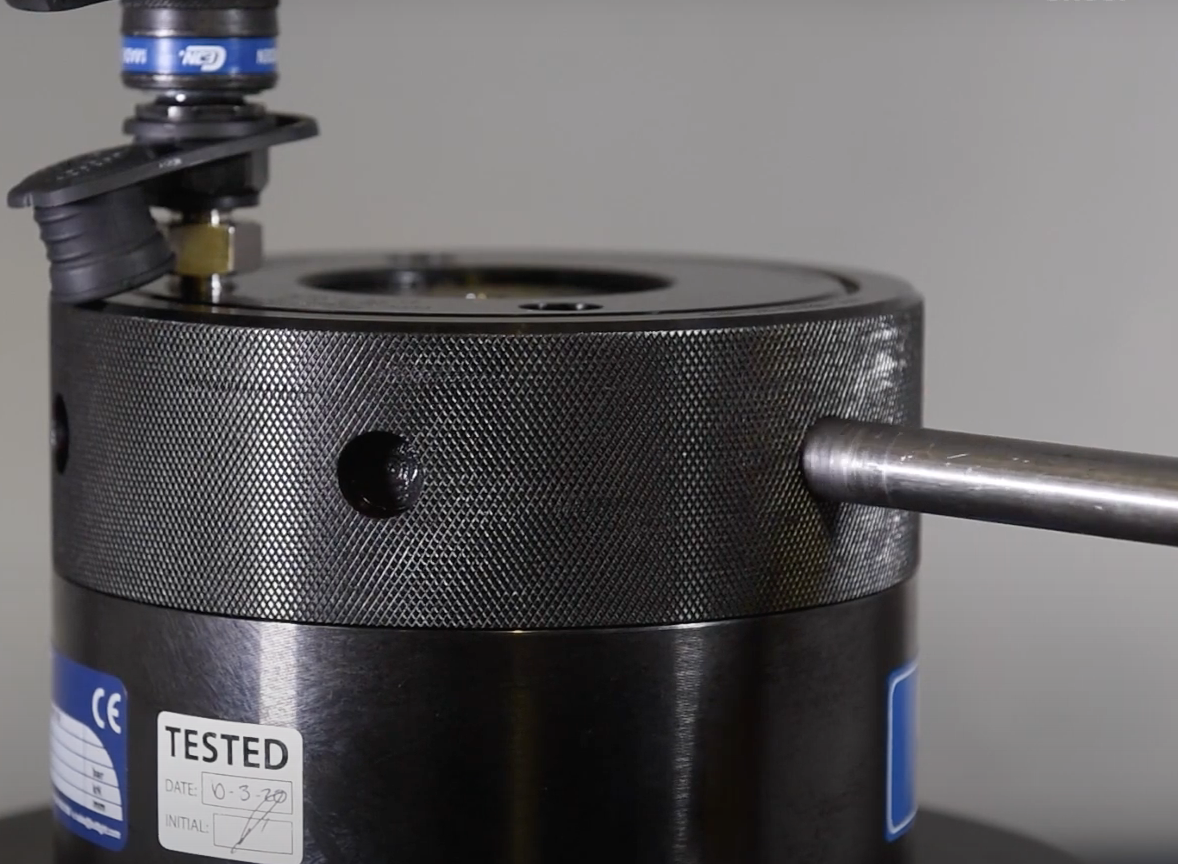

Hydraulic Nuts

Hydraulic nuts allow large-diameter bolts to be easily tensioned with high and precise preload.

A hydraulic pump activates the internal coupling system, reducing the effort required to tighten a large bolt to just the effort needed to operate the pump. Since there is no nut rotation during tightening, the operation can be performed in limited spaces, eliminating thread damage caused by torsional forces. Multiple hydraulic nuts can be connected simultaneously, ensuring that all bolts in the joint are equally loaded with the same high and precise preload.

Features

- Available in lower ring, upper ring, and wedge types.

- Standard designs: 1500 and 2500 bar.

- A20/A15 range.

- It replaces the original nut; it combines the tensioner and permanent nut.

- All-in-one solution; the nut remains in place after tensioning.

- Custom designs available.

- Sizes up to M400 available (currently), with larger sizes under evaluation.

- High-temperature solutions available.

- Quick and easy installation.

- Even and precise load distribution due to its hydraulic design.

- Low initial load loss (wedge type).

- No torque tightening or tensioning.

- No heavy hammers or spanner wrenches required.

- Self-alignment (wedge type).

- Enhancement of fatigue coefficient performance.

- 100% simultaneous tensioning.

- Durable internal coupling – highly compact and cost-effective.

- Requires a shorter stud length than conventional tensioners.

Request a Quote

Us

Us Torque Academy

Torque Academy