Standard Bolt Tensioners.

Designed for general use in surface applications.

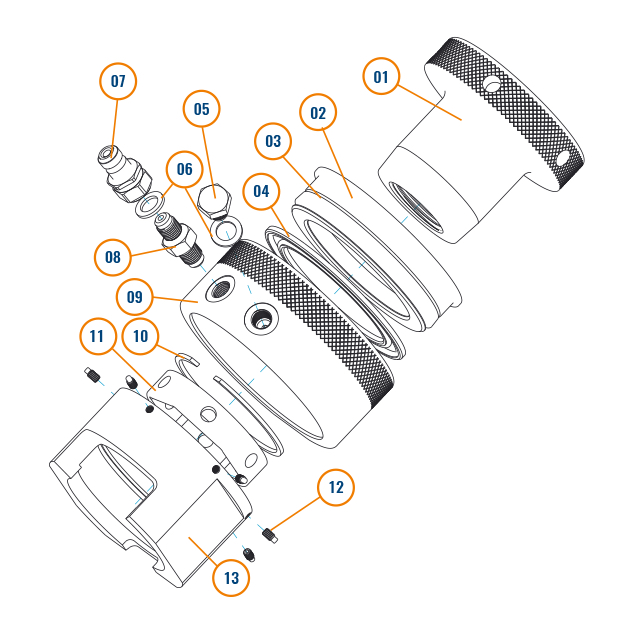

Each tool comprises a hydraulic cylinder, bridge, puller, and socket. Interchangeable adapter kits feature a common hydraulic cylinder capable of tightening multiple bolt sizes.

Features:

- A tensioner engages with the bolt or stud.

- High-pressure hydraulic components are used to axially elongate the bolt.

- The stretching or elongation of the bolt creates the clamping force; as the bolt is stretched, the nut lifts from the flange.

- An access window in the tensioner allows the nut to be turned with minimal friction.

- When hydraulic pressure is released, the nut retains the bolt's elongation, maintaining the "load."

- Tension is applied directly by elongating the bolt, eliminating friction.

- The applied load is controlled with high precision, as it is directly proportional to the pressure applied to the hydraulic bolt tensioner.

- The loss of load between the applied and retained load after tensioning is approximately 20% less than the frictional loss associated with torque.

- Accurate residual load outcomes due to calculable load loss.

- Tensioning can be repeated.

Request a Quote

Us

Us Torque Academy

Torque Academy