Test bench for torque wrenches and screwdrivers.

FTY the first test bench on the market that can simulate tightening in all its conditions.

- Tool testing: wrenches (electronic/digital, click), hydraulic and battery-powered tools, impulse tools (excluding impact wrenches).

- Automatic detection of the click point on click-type torque wrenches.

- Statistical Process Control: Machine capability measurement (Cm, Cmk) and X, R charts.

- Test according to ISO 6789 and ISO 5393 standards.

- Testing screwdrivers up to 2000 rpm.

- Comparative tests for screwdrivers and wrenches with comparison of torque (and possibly angle between the bench and the tool under test.

- Testing in both clockwise and counterclockwise directions.

- External transducer connectivity for special testing applications.

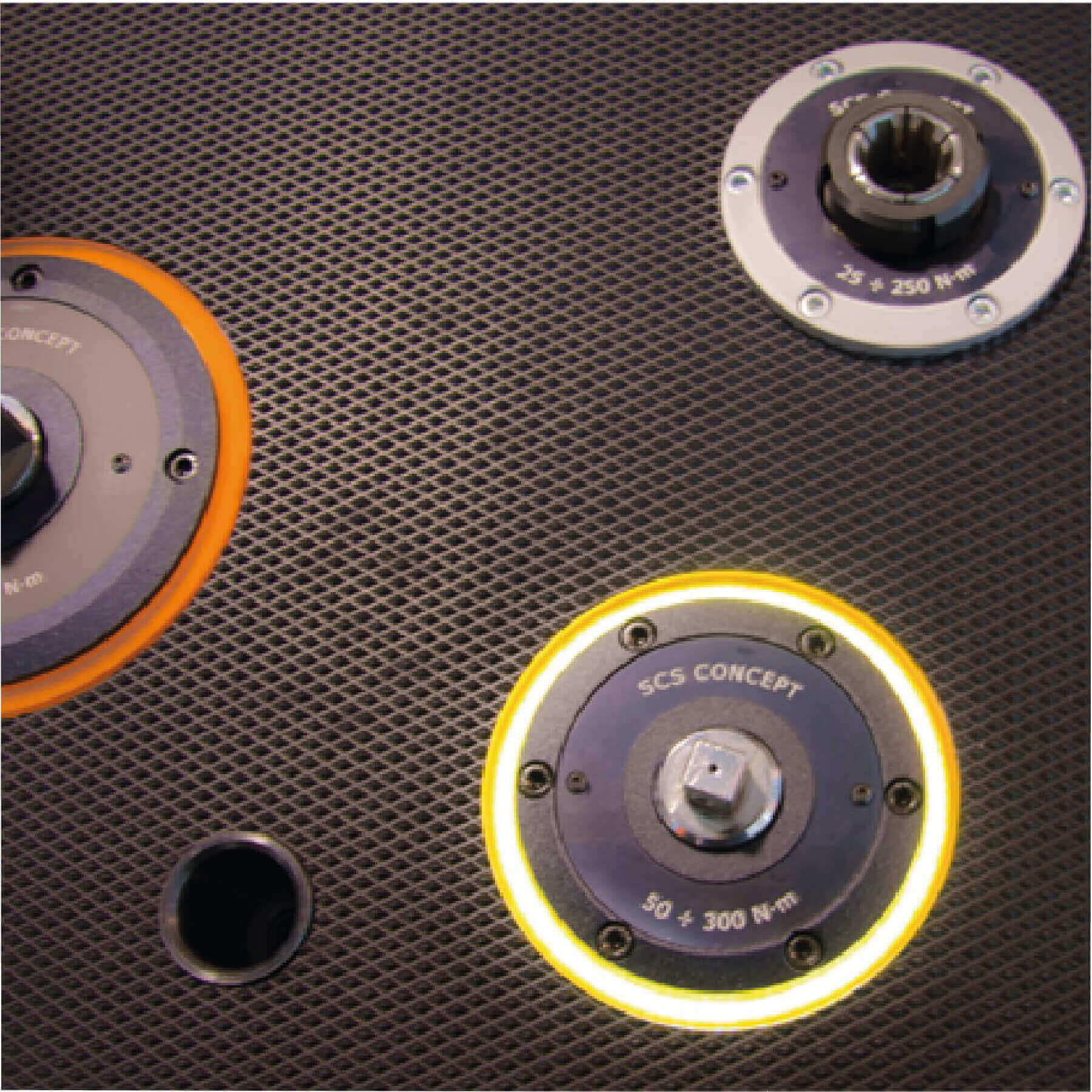

- Reaction system for testing and calibration of torque wrenches.

- Linear simulation of the joint (30 to 720 degrees) and nonlinear simulation of torque/angle characteristics (for multi-stage tools or dominant torque simulation).

- Database with tool archive, test planning and execution, results storage.

- Mechanical joint simulators for testing impulse tools with shut-off valve.

- Statistics and reports.

- Real-time plots displayed on the monitor.

- Equipped with dynamic transducers (hydraulic brakes) and static torque transducers configured according to the tools to be tested on the production line.

- Local or remote programming using management software for quality control of the production line.

- Radio communication with external systems.

- Local or server-based database.

- Torque accuracy below 0.5% according to DIN 51309 standard.

- Angle accuracy less than 0.25° according to VDI/VDE 2648.

- Battery-powered.

Request a Quote

| Product | Analysis, Verification & Audit |

|---|---|

| Application | Audit, Quality, Maintenance |

| Industry | Aerospace, Automotive, Manufacturing |

Us

Us Torque Academy

Torque Academy