From Paper to Digitalization – Augmented Reality

For generations, work instructions guided every step of production on fragile pages of paper, prone to wear and tear, misunderstandings and human error. The result? Inconsistent quality, wasted time and inefficient workflows that stifled productivity and innovation.

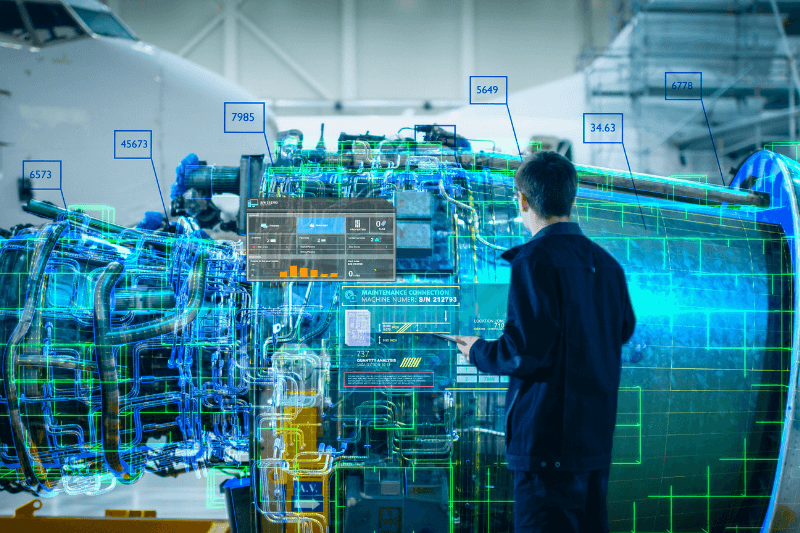

Over time, paper instruction manuals were replaced by digital work instructions. Today, digital technology is sweeping manufacturing plants, replacing paper with interactive displays, mobile devices, and even augmented reality.

Digital work instructions provide manufacturers with a way to streamline their processes and improve efficiency. By using digital workflows, manufacturers can reduce the amount of time it takes to train new employees and can ensure that all employees follow the same procedures.

What are Digital Work Instructions?

Digital work instructions are electronic versions of work instructions and standard operating procedures (SOPs) that transform static paper documents into dynamic, interactive tools. They guide workers through complex manufacturing, maintenance, and service processes by providing real-time, step-by-step instructions—complete with visual aids and contextual information—on how to best complete a task. These digitized work instructions and procedures are stored in a centralized system so workers can easily access them to perform tasks or make project decisions.

Key Benefits of Digital Work Instructions

- Digital work instructions are paperless work instructions that can be accessed via an electronic device such as a PC, monitor, tablet, smartphone, or augmented reality device. They provide relevant step-by-step information in a visual and easily digestible format, replacing outdated paper procedures.

- They help frontline workers perform any task that requires following a standard operating procedure (SOP), from assembly to inspection and maintenance.

- Digital work instructions are as much about knowledge transfer as they are about process documentation.

- They can be customized to meet the needs of individual workers and can be used to collect data on worker performance.

- Digital workflows can be augmented with visual aids, contextual information, and augmented reality experiences to support intelligence.

Us

Us Torque Academy

Torque Academy